Welcome to the Construction Report

Please select a section from the navigation menu to view more information about the Ventus 2c 3.6m model.

Model Selection Criteria

Model Selection Criteria In 2022, I went through all the offers as they were currently available. The search was: a full GRP/CFRP model that does not have too high wing loading. Not too big, maximum 4 m wingspan so that it can be easily transported. It should be able to be used for extended thermal flights, but then be fast and stable in performance phases to be able to really let off steam. Well, that's contradictory, isn't it? Oh yes, I added scale model to the search :-) This limits the spectrum to designs such as ASW 17, ASW 27, Ventus 2c, Glasflügel, DG 1001, ASW 19, ASH26 champ, ASW 20, DG 600

Checked manufacturers in the final selection 2022: Valenta, Flight Composites, Composite RC gliders, Valenta, Paritech, Tangent MG, emc vega

At first only as a sailor, because I am one of those who is reluctant to saw off the nose. Then I accepted it reasonably. After all, there are more and more FES drives for the man-carrying, so that the scale can be maintained, as far as possible

Order and delivery

After careful comparison, the choice was made and the order went out to Composite RC Gliders with the glider version with battery + 11 KST servos + EZ vehicle for € 2100.00 in 2022

Ventus 2c 3.6 Composite RC Gliders Switch to EnglishThe delivery was prompt! (Praise)

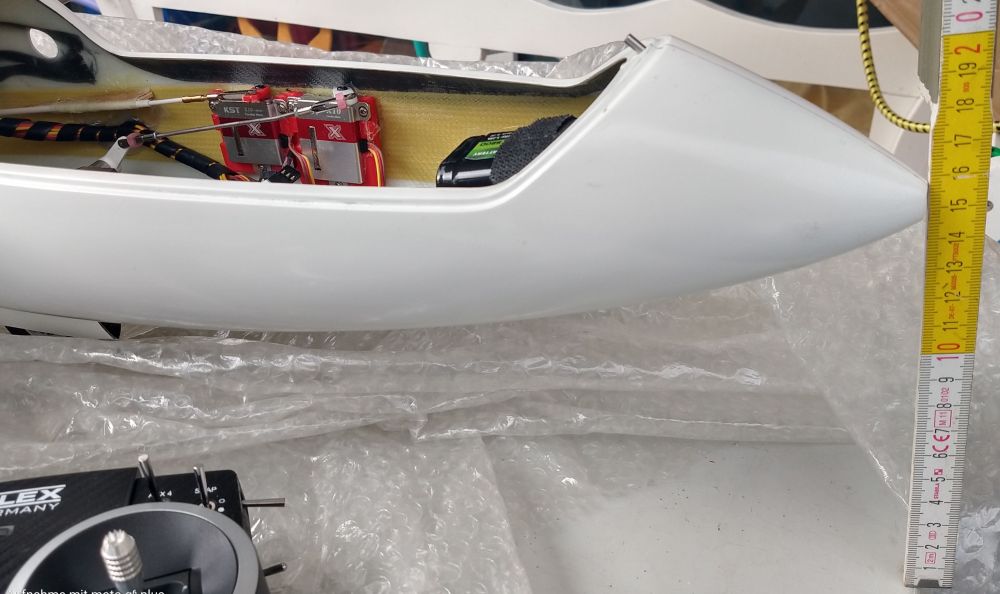

The model was packed with a lot of bubble wrap, which was very well sized. The model arrived undamaged.

There were the following shortcomings:

The wing insertion did not fit. On request, it was recommended to rework the tube, i.e. remove glue and mill larger holes, re-resin. Well

Another shock: the flaps jammed. I thought it could come through transport. And I let the surfaces "relax" for a week, and lo and behold, after that nothing jammed anymore. Phew!

Repaired areas can be seen on the fuselage, the surface is not perfect. When removing it from the mold, there were probably problems here

build it

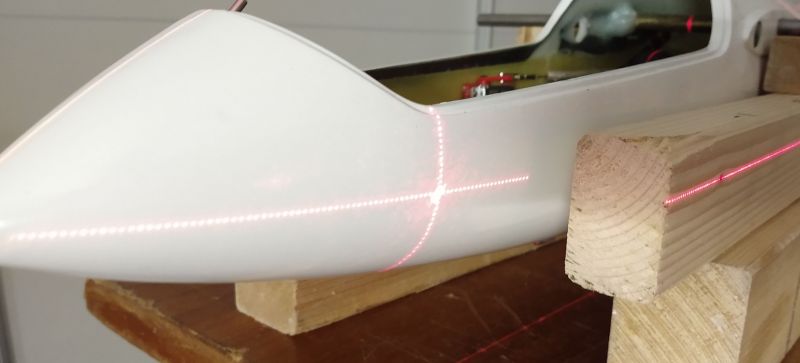

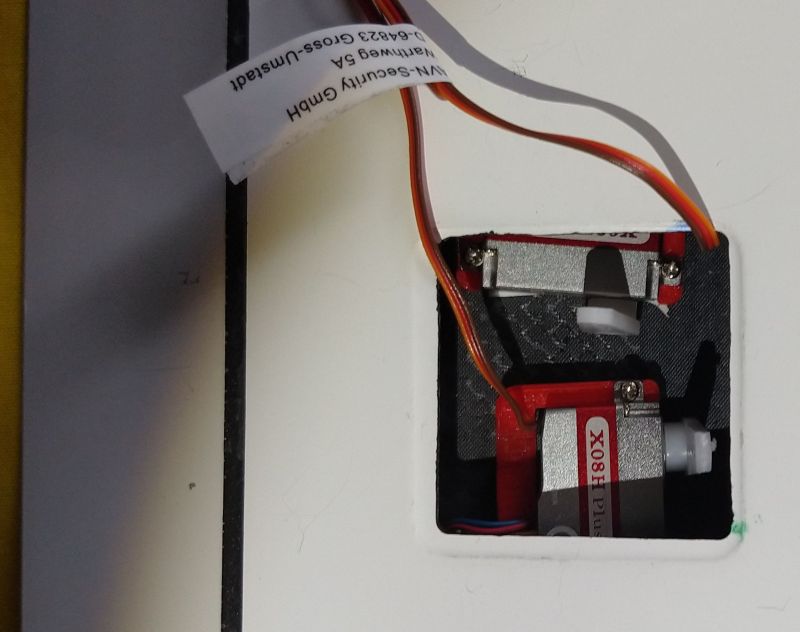

The website provided enough information for an experienced modeler to complete the model. A weak point generally accepted by the model builders' community is also the SUB-D connectors from the computer industry. These were used for PCs, in times before USB, for connecting monitors/printers, and were secured WITH 2 SCREWS to prevent them from slipping out. And you need them, how often have I been ordered here by PC users, because the plug had come loose. Model builders generally omit this threadlocker. I cannot accept this solution, through a small gap between the fuselage and the root rib of 2-3 mm, the servos can already stop, and a crash is inevitably inevitable. No thank you! So I made a new connector and created a screw connection to the fuselage. The cable can move a little in the wing, so that you can quickly mount the wings.

Another weak point: linkage of the elevator, with the materials that were there, there is a danger that the rudder horn, which is only attached by glue, and thus only one side is fixed, can detach in flight. I glued it on one side, and then secured it on the other side with a cotter pin

The model was initially built as a glider, and subsequently equipped with a Reisenauer drive. That's why I have data from these two versions. (Reference: Glider/Electric)

Weights:

Wings (Segler+Elektro):1052g left + 1068g right = 2120g

Fuselage (Segler): 1880 g

Flying weight complete (glider): 4,000 kg with steel wing connector. Listed on website as 3,700 g

Weight fuselage (Elektro): 2.152 g CFK

Weights all (Elektro): 4.280 g

Weights wing connector CFK/steel 44/200 g

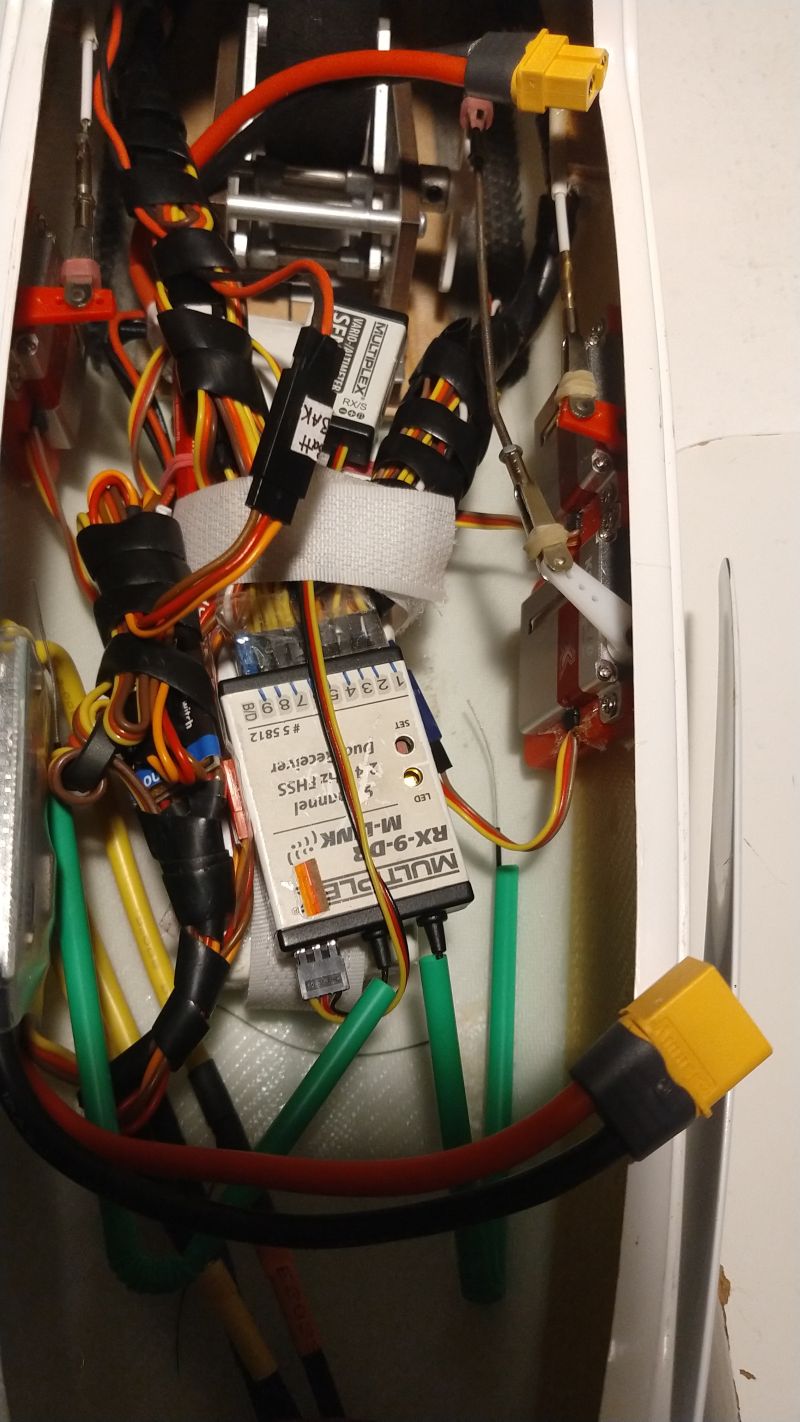

Modification Electric

further construction

First flights

First Flight! the hand launch was successful on the slope, I trimmed in flight and landed again. Ailerons needed strong trim, because it is so difficult to judge before the first take-off whether it is perfectly equal left and right. The elevator had to be trimmed more downwards. With a larger battery, I have eliminated the problem and have a longer motor runtime. Going there, the flaps were already perfectly compensated with the elevator, I took over the mixer setting directly from another model.

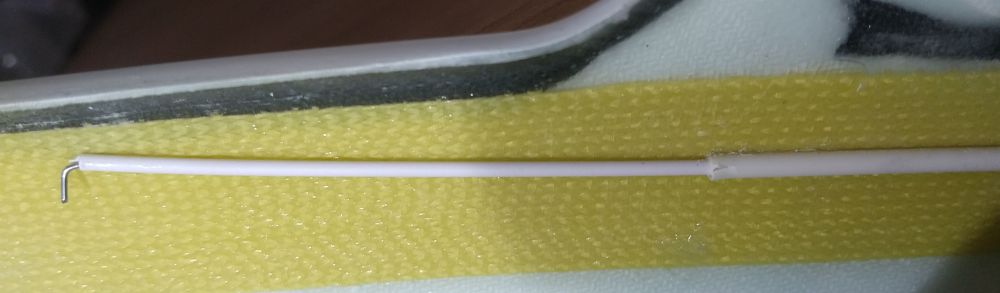

After landing, I checked everything again thoroughly and found another construction error: The elevator was unintentionally trimmed upwards. I didn't understand that at first, but after a few days of pondering it became clear to me what had happened here. Please don't copy this construction error: The Bowden cable was soldered to the inner steel wire at one end, and it was crimped at the other end. This is not very well tolerated, I have found out that under strong tensile load, the steel wire pulls minimally out of the plastic Bowden cable. This results in a permanently incorrect trim! Remedy: Either solder both or crimp both. The mixed form is dangerous.

Start afterwards the Ventus can be started well by hand. But with a model of this price range, I like to have both hands on the control sticks when I hand it over to its habitat. I have a complete EMC-Vega flange with foot switch available if there is no turret

Flight

the thing is fast, my wing loading is calculated at 73 g/cm 2. So as with the large models, you should divide up the space and fly ahead.

Landings Configuration: it is recommended to set flaps at least 50%. On a narrow runway, e.g. on a slope, wheel retracted to increase the braking effect and so that it does not turn on the ground or roll longer. starvation speed. The double brake flaps look BRUTAL. It's better not to go out at full speed, only in an emergency. A little tact is required here

Conclusion

Model is now as it corresponds to my ideas. When building, I removed all errors without compromise, and built in a lot of security. Connector screwable, backup battery with HEPF Voltario T60...

All flights were problem-free, the model is good in the air. With fully extended flaps also without any problems, it gets a little slower. In general, I have been flying the Ventus at sufficient speed so far, I was just once at the limit.

Here is some data about the resulting model as a summary

| Parameter | Value |

|---|---|

| Span | 3600 mm |

| Airfoil | Eppler 205 strak E195 |

| Wingload Segler/elektro | 68/73 |

| Servos | 11 Stück digital KST high voltage |

| Price (2022) | € 2100 incl Versand |

| Engine | Reisenauer |

| Drag | 35 N(ewton) bei 4S LiPo |

| Prop | 20x13, Motor Leopard LC5001750JV mit MicroEdition 5:1 |

| ESC | Sunshine ICE-100A BCE out 7,4V |

| Engine total price | € 400 |

| batteries | LiXX Akkus 2...6 Zellen |

| Imax [A] at ground | 42 bei 100%, at 50% 25A |

| Battery used | 4S 4000 mAh SLS |

| Backup NiMH | 4,8V Eneloop |

| calc. run time | 8 min bei Halbgas |

| Engine temp | 3 min = 50 degr. |

| ESC temp | 37 Grad |

| Supply | HEPF Voltario T60 redundant |

| Standby current [mA] | min 250 , peak 1200 |

| Reisenauer data | 4656 RPM, 52 Ampere, 770 Watt, draft 510 N |